Add products by adding codes

The offer applies to the CATERPILLAR sensor regeneration service.

Before placing an order, please contact us to determine the details of the regeneration process.

phone: +48 503 302 310, email: info@proengines.eu

The regeneration process

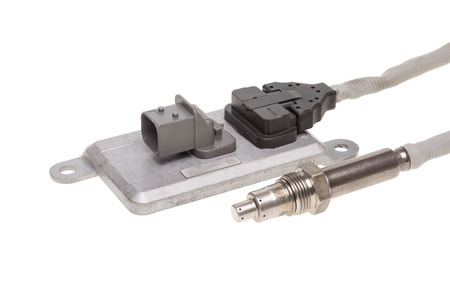

The highest quality is a priority for us! To get the highest quality product, each sensor is dismantled for the first part. Then it is cleaned, painted and regenerated. Metal probe is replaced with a completely new one. Regeneration is carried out on the original components and software.

The entire process is performed by the best specialists and with the utmost care. The device is functional and tested.

Invoice

We issue a 23% VAT invoice for each part purchased. EU customers 0% VAT (VAT id must be acitve)

Size (with packaging)

Weight: 0,5 kg

Length: 20 cm

Height: 11 cm

Width: 9 cm

If you have any questions, please contact us

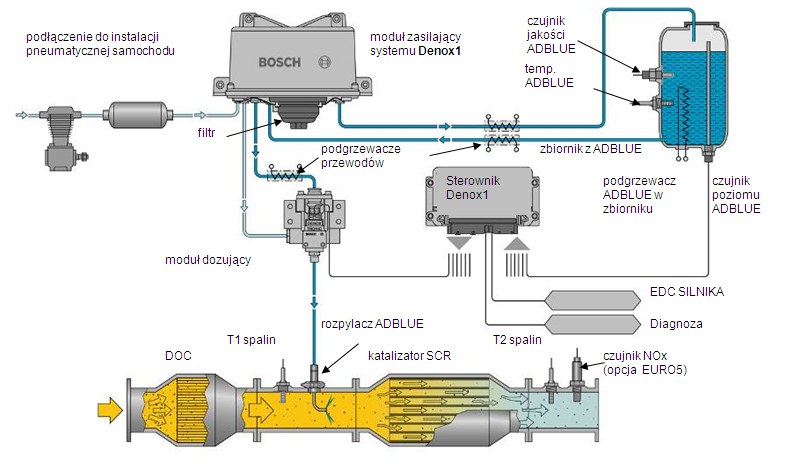

SCR technology

SCR technology consists in converting (reducing) nitrogen oxides into non-toxic nitrogen and water vapor in a catalyst using ammonia as a reducer. In commercial vehicles, a non-toxic, odorless, 32.5% aqueous solution of urea is used. Under the control of the engine management system, the urea solution (NOX), stored in a separate tank, is dosed in the desired amounts into the hot exhaust stream. Under high temperature exhaust gases, the urea solution decomposes to ammonia and carbon dioxide. Ammonia then reacts with nitrogen oxides to form free nitrogen and water vapor.

Denoxtronic Bosch systems have been used since 2004 in trucks equipped with diesel power systems. They add AdBlue to the SCR catalyst to reduce NOx emissions from exhaust gases by up to 85%. As a result, lorries meet the exhaust emission standards from Euro 4 to Euro 6.

source: www.bosch.com